Flexibility and efficiency: prototyping, small, medium and large series

Innovation, efficiency and flexibility are the characteristics that allow us to respond promptly and effectively to customer needs. The availability of our systems and the versatility of our knowledge make PEL a strategic resource for customers.

To satisfy every request, we always take into account the specific needs of the project and provide a team of technicians specialized in design, forging mechanical processing, assembly and testing.

Raw materials

We can process a multitude of metal alloys, including those with low lead content or lead-free (ECO).

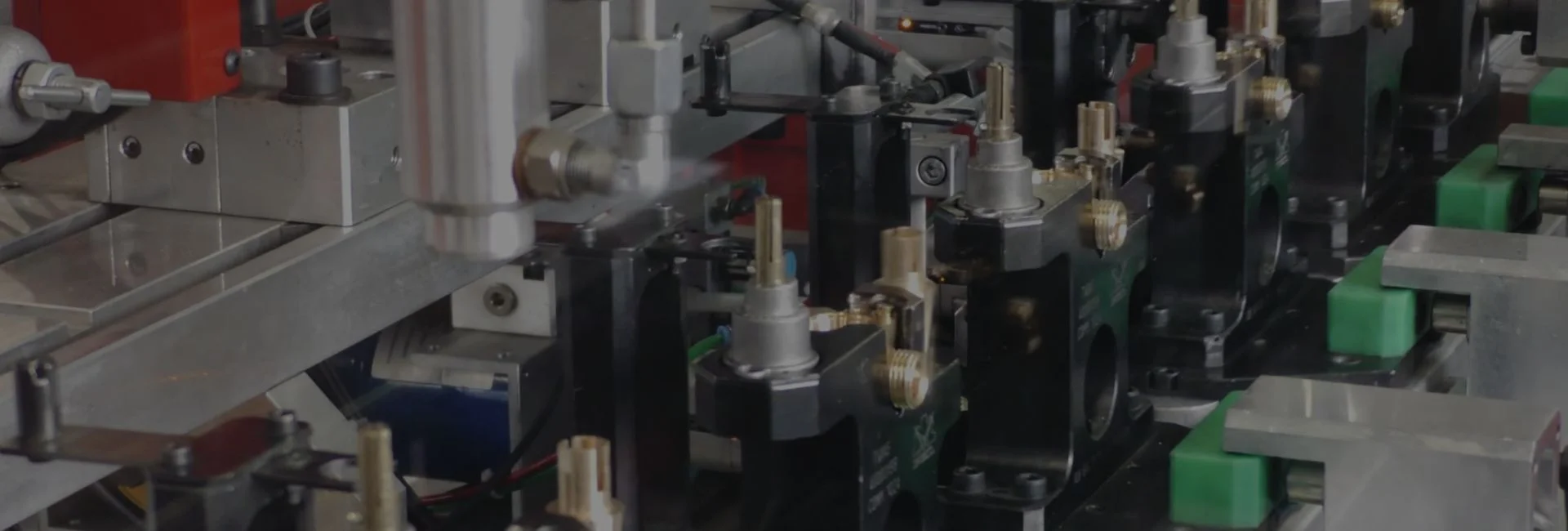

Internal mechanics

In the internal mechanical department we design and build all the equipment necessary for series production. A special department is dedicated to the creation of assembly and testing machines.

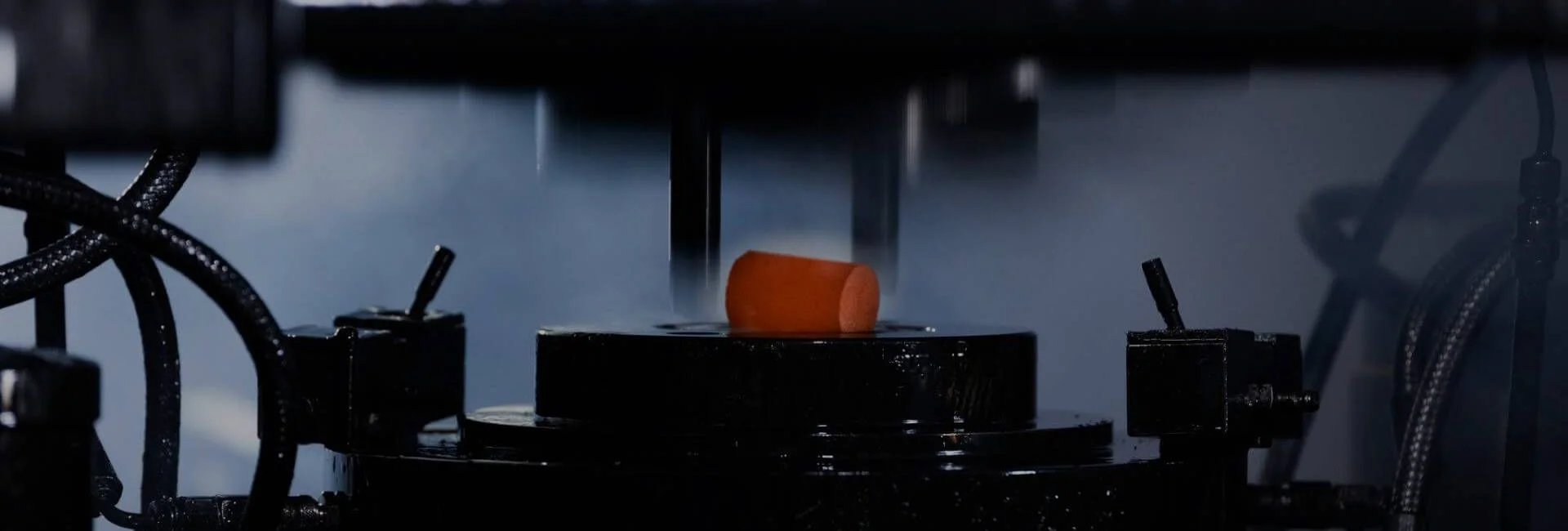

Hot forging

The hot forgin process integrated into the company is carefully monitored. The effectiveness is supported by the use of simulation software for a stable and safe result.

Mechanical machining

Processing for chip removal takes place with the use of CNC transfers and lathes. The fleet of machines is of the latest generation and offers a very high production capacity.

Assembly and testing

PEL assembles and tests each component created to always ensure excellent products, capable of meeting all the technical needs of the project.

Outsourced services

We also offer services dedicated to the machining, treatments and surface finishing of components thanks to reliable and capable district partners.

Logistics and distribution

PEL has warehouses in Europe and the United States in order to guarantee efficient distribution of the product in the ways requested by customers, including the consignment-stock service.